Thursday, 21 November 2024

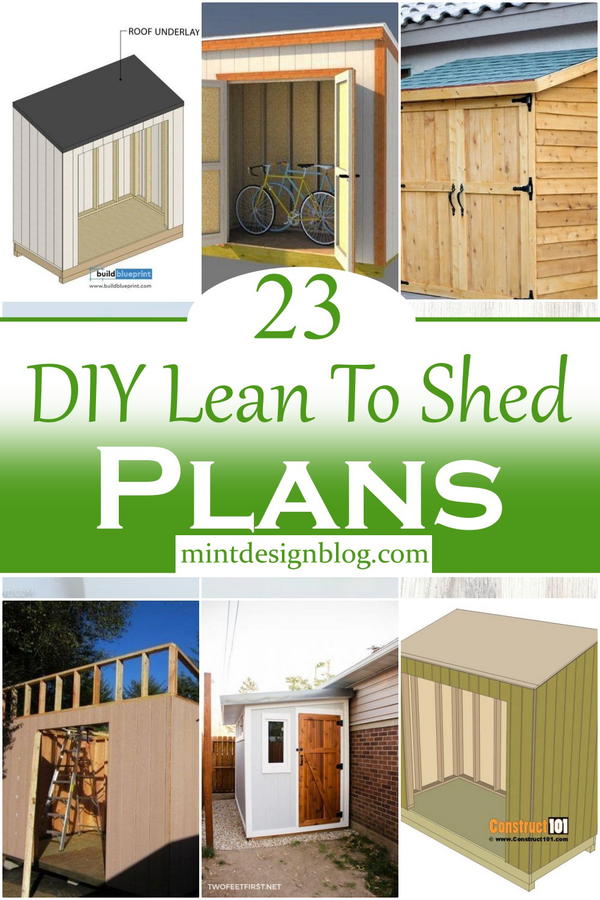

How to Build a Lean-To Shed: A Quick and Easy DIY Storage Project

How to Build a Lean-To Shed: A Quick and Easy DIY Storage Project

Constructing a lean-to shed offers a straightforward and cost-effective solution for expanding storage capacity on your property. This guide provides a comprehensive walkthrough of the process, detailing each step from initial planning to final finishing touches. While seemingly simple, meticulous attention to detail is crucial for ensuring a sturdy and weather-resistant structure. This detailed plan assumes a basic level of DIY experience and access to common hand and power tools.

Phase 1: Planning and Preparation

The success of any building project hinges on thorough planning. Before commencing construction, several key considerations must be addressed.

Site Selection and Assessment

The location of your lean-to shed significantly impacts its functionality and longevity. Consider factors such as:

- Proximity to the main structure: Ensure easy access and minimal distance for connecting utilities if needed.

- Ground stability: Avoid areas prone to flooding or significant soil erosion.

- Sunlight and shade: Opt for a location that balances sunlight for drying and shade to prevent overheating.

- Local building codes and regulations: Check with your local authorities for any permits or restrictions that might apply to shed construction.

Materials Selection and Quantity Estimation

Accurate material estimation prevents costly delays and waste. The following list provides a basic outline; quantities will vary based on the desired dimensions of your shed:

- Pressure-treated lumber: For the frame, including posts, beams, rafters, and supports. Choose appropriately sized lumber based on the anticipated snow load and wind exposure. Check for appropriate grading and treatment specifications.

- Plywood or OSB sheathing: To cover the walls and roof, providing structural integrity and a surface for siding or roofing materials.

- Roofing material: Options include asphalt shingles, metal roofing, or corrugated plastic. Consider durability, cost, and aesthetic preferences.

- Siding material: Choose from various options, such as vinyl, wood, or metal, considering budget and desired aesthetic.

- Fasteners: Include galvanized nails, screws, and appropriate bolts for connecting framing members and attaching siding and roofing.

- Concrete or gravel base: For a stable foundation. Gravel offers a cost-effective option for smaller sheds.

- Waterproofing membrane (optional): Provides added protection against moisture damage under the roofing material.

- Paints and sealants: For protecting the wood from the elements and enhancing the aesthetics of the finished structure.

Tool Acquisition and Preparation

Ensure you have the necessary tools before starting construction. This will streamline the process and avoid unnecessary interruptions:

- Measuring tape and level: Accurate measurements are critical for a structurally sound shed.

- Shovel and post-hole digger: For preparing the foundation.

- Circular saw, reciprocating saw, and hand saw: For cutting lumber to size.

- Drill and various drill bits: For driving screws and creating pilot holes.

- Hammer and nail gun (optional): For fastening framing members and sheathing.

- Safety glasses and work gloves: Essential for protecting against injuries.

Phase 2: Construction

Foundation Preparation

A stable foundation is paramount. This involves:

- Leveling the ground: Remove any unevenness or debris from the chosen site.

- Creating a base: Pour a concrete slab or lay a bed of compacted gravel, depending on the size and weight of the shed. Ensure the base is level and extends beyond the footprint of the shed to provide stability.

Frame Construction

The frame provides the structural support of the shed. The process typically involves:

- Erecting support posts: Securely embed the posts into the ground or foundation using concrete or heavy anchors. Ensure they are plumb and evenly spaced.

- Attaching beams and rafters: Construct the framework using pressure-treated lumber, ensuring all connections are strong and secure. Use appropriate fasteners and check for squareness and level throughout the process.

- Adding wall supports: Install vertical supports to add rigidity to the walls, creating a robust structure able to withstand wind and snow load.

Sheathing and Roofing

Once the frame is complete, attention shifts to enclosing the shed:

- Installing sheathing: Attach plywood or OSB sheathing to the walls and roof, ensuring proper overlap and secure fastening. This creates a solid base for the outer layers.

- Applying roofing material: Install chosen roofing material according to manufacturer's instructions. Pay close attention to sealing overlaps to prevent leaks.

- Adding a waterproofing membrane (optional): Place a waterproof membrane beneath the roofing material for enhanced protection against moisture.

Siding and Finishing

The final steps focus on the exterior and interior finishing:

- Installing siding: Cover the exterior walls with the chosen siding material, ensuring proper overlap and alignment.

- Adding doors and windows (optional): Install doors and windows, ensuring proper sealing and weatherproofing.

- Painting or staining: Protect the wood with paint or stain, enhancing both durability and aesthetics.

- Interior finishing: Add shelving or other interior features as desired. Consider painting or staining the interior to enhance the look and protect the wood.

Phase 3: Inspection and Maintenance

Upon completion, conduct a thorough inspection to ensure structural integrity and address any deficiencies. Regular maintenance is key to extending the life of your lean-to shed:

- Annual inspections: Check for signs of damage, such as loose boards, leaks, or pest infestations.

- Repairs as needed: Address any damage promptly to prevent further deterioration.

- Cleaning: Regularly clean the shed to remove debris and prevent mold growth.

Building a lean-to shed is a rewarding DIY project that provides valuable additional storage space. By following these detailed steps and paying meticulous attention to detail, you can create a durable and functional structure that enhances your property for years to come. Remember to always prioritize safety and consult professional guidance if necessary.

How to Make a Small Pallet Shed: Affordable Plans for DIY Builders

How to Make a Small Pallet Shed: Affordable Plans for DIY Builders

Hey there, fellow DIY enthusiasts! So you're dreaming of a little extra storage space, but the thought of those pricey pre-built sheds is making your wallet weep? Fear not! We're going to build a fantastic, functional, and *affordable* small pallet shed together. This project is perfect for beginners, and the best part? We’re reusing pallets, making it super eco-friendly too! Let's dive in!1. Planning Your Pallet Shed Paradise

Before we even think about hammering a nail, let's get organized. This step is crucial for a successful build. Think of it as laying the foundation (pun intended!).1.1 Determining the Size and Location

First things first: how big do you need your shed to be? A small pallet shed is perfect for tools, gardening supplies, or even a mini workshop. Consider what you'll be storing to determine the appropriate dimensions. Remember, smaller is often easier to build! Next, choose your location carefully. Consider sunlight exposure, access, and proximity to power sources (if needed). Make sure you have enough room to work comfortably around the area during construction.1.2 Gathering Your Materials

The beauty of a pallet shed is its reliance on recycled materials. Here's what you'll primarily need:- Pallets: The number of pallets you'll need depends on the size of your shed. Aim for sturdy, heat-treated pallets (look for the HT stamp). Inspect them carefully for any rot or significant damage. You might need 8-12 pallets for a small shed, but it could vary.

- Screws: Lots of them! Get a good mix of lengths to accommodate different thicknesses of wood. Exterior-grade screws are recommended for durability.

- Hammer and nails (optional): While screws are preferred for sturdiness, a hammer and nails can be useful for certain aspects, especially if you have some more rustic pallets.

- Measuring tape and level: Essential for accurate measurements and ensuring your shed is plumb.

- Saw (circular saw or hand saw): You'll likely need to cut some pallets to size.

- Drill with screwdriver bits: For driving in those screws efficiently.

- Safety glasses and gloves: Protect yourself from flying debris and splinters.

- Plywood or OSB (optional): For the roof and potentially the back/side walls if needed for weather protection.

- Roofing material (optional): For added weather protection; tarps, corrugated plastic sheets, or even salvaged roofing material work great.

- Soil sealant (optional): If the ground is likely to be damp

1.3 Sketching Your Design

Don’t worry about being an architect! A simple sketch of your shed's dimensions and how the pallets will be arranged is sufficient. This will be your guide throughout the building process. Consider a simple rectangular design for ease of construction. Think about whether you want a single door or a double door.2. Building Your Pallet Shed

Now for the fun part! Remember, safety first! Wear your safety glasses and gloves throughout the entire process.2.1 Building the Base

This depends on your ground conditions. If the ground is level and firm, you can lay your pallets directly on the ground. However, it's a good idea to level the ground using gravel or pavers before placing the pallets. To make it a bit more permanent, consider setting your pallets on a base of pressure-treated lumber, creating a frame before placing the pallets down.2.2 Assembling the Walls

Start by assembling the side walls, creating a rectangular frame using several pallets. Secure the pallets together using screws â€" plenty of them! Try to stagger the gaps between pallets for added strength and a more visually appealing result. For a more weather-resistant structure, consider adding plywood or OSB sheeting between the pallets.2.3 Constructing the Roof

This is where you’ll need to get creative. A simple gable roof is easiest. You can use more pallets or even plywood/OSB for the roof structure. Remember to create an overhang to protect the walls from rain. Once the roof framework is built, add your chosen roofing material (tarps are a great budget-friendly option).2.4 Adding the Door

You can use a single pallet as a door, or create a more complex door structure using several pallets. Attach hinges to the door frame and the shed wall. Consider adding a simple latch or lock for security.3. Finishing Touches

Once your basic structure is complete, it’s time to add the finishing touches:3.1 Sanding and Cleaning

Give your shed a good sanding to smooth out any rough edges. Clean the pallets with soap and water, removing any dirt or debris.3.2 Painting or Staining (Optional)

Adding a coat of paint or stain will improve the aesthetics and protect the wood from the elements. Choose weather-resistant options for longevity.3.3 Sealing (Optional)

Sealing your pallet shed will further protect it from moisture and extend its lifespan.Commonly Asked Questions

Q: How long does it take to build a pallet shed?

Depending on your experience and the shed's complexity, it could take anywhere from a weekend to a few weeks.

Q: How much does it cost to build a pallet shed?

The beauty of this is the low cost. Your main expenses will be screws, other hardware, and potentially roofing materials. You can keep the cost extremely low by using reclaimed/recycled materials.

Q: Are pallet sheds durable?

With proper construction and weather protection (roofing, sealing, paint), a pallet shed can last for several years. The durability depends heavily on the quality of the pallets you use.

Q: What kind of permits do I need?

Permit requirements vary by location. Check with your local authorities to determine if you need any permits before starting your project. Smaller sheds are often exempt.

Q: Can I use any type of pallet?

It's best to stick to heat-treated pallets (marked HT). Avoid chemically treated pallets, as they may contain harmful substances.

And there you have it! Your very own affordable and eco-friendly pallet shed. Remember to enjoy the process and don't be afraid to get creative. Happy building!Shed the Old, Build the New: DIY Lean-To Shed Plans for Your Backyard

Shed the Old, Build the New: DIY Lean-To Shed Plans for Your Backyard

The allure of a well-organized backyard, free from clutter and overflowing with potential, often motivates homeowners to seek additional storage solutions. A lean-to shed, nestled against an existing structure such as a house or garage, presents an elegant and efficient solution. This comprehensive guide provides detailed plans and instructions for constructing your own DIY lean-to shed, maximizing space and functionality while minimizing cost and effort. From initial planning and material selection to construction and finishing touches, we will navigate each step of the process, empowering you to transform your outdoor space.

Phase 1: Planning and Design

Before embarking on any construction project, meticulous planning is paramount. This phase involves determining the ideal location, dimensions, and features of your lean-to shed, ensuring it aligns with your needs and local building codes.

Site Selection and Considerations

The location of your lean-to shed significantly impacts its usability and longevity. Consider the following factors:

- Proximity to the existing structure: Choose a location that allows for easy attachment to the main building, minimizing material waste and maximizing stability.

- Accessibility: Ensure easy access for material delivery and future use. Consider the proximity to power sources if you plan on incorporating electrical components.

- Sunlight and drainage: Select a site with adequate sunlight for natural ventilation and proper drainage to prevent water accumulation around the foundation.

- Local building codes and regulations: Consult your local authorities to ensure your planned dimensions and construction methods comply with all relevant regulations. This may include setbacks from property lines and height restrictions.

Determining Dimensions and Features

The dimensions of your lean-to shed should reflect your storage needs and the available space against the existing structure. Consider the following aspects:

- Length and width: Determine the amount of storage space required. A typical lean-to shed might range from 6ft to 12ft in length and 4ft to 8ft in width, but this is highly customizable.

- Height: The height should allow for comfortable access and storage of items. Aim for a minimum height of 6ft at the highest point to comfortably work inside.

- Door size and placement: Consider the size and placement of the door to optimize access and avoid obstructions within the shed.

- Roof design: A simple single-slope roof is common for lean-tos, providing efficient rainwater runoff. Consider the angle of the slope to ensure sufficient drainage.

- Windows (optional): Incorporating small windows can enhance ventilation and lighting.

Material Selection

The choice of materials significantly influences the cost, durability, and aesthetic appeal of your lean-to shed. Popular options include:

- Framing: Pressure-treated lumber is recommended for its resistance to rot and insects. Consider using 2x4s or 2x6s depending on the size and anticipated load.

- Sheathing: Plywood or OSB (Oriented Strand Board) provides a sturdy and cost-effective sheathing for the walls and roof.

- Roofing: Asphalt shingles are a common and relatively inexpensive roofing material. Metal roofing offers superior durability and longevity but is generally more expensive.

- Siding: Various siding options are available, including vinyl, wood, and metal. Consider factors such as cost, maintenance, and aesthetic preferences.

- Foundation: A concrete slab foundation offers the most stability, but a gravel base can be a more cost-effective alternative.

Phase 2: Construction

With the planning complete, the construction phase begins. This involves careful execution of each step, ensuring structural integrity and adherence to the design plan.

Foundation Preparation

A stable foundation is crucial for a long-lasting lean-to shed. Whether opting for a concrete slab or a gravel base, proper preparation is essential:

- Leveling the ground: Ensure the ground is level to prevent uneven settling and potential structural issues.

- Gravel base (optional): If choosing a gravel base, create a compacted layer of gravel at least 4 inches deep.

- Concrete slab (optional): Follow the instructions for pouring a concrete slab, ensuring proper curing time before proceeding with the frame construction.

Framing the Structure

The frame provides the skeletal support for your lean-to shed. Accurate measurements and precise cuts are critical for a sturdy and well-aligned structure:

- Building the base frame: Construct a rectangular frame on the foundation, ensuring squareness and accurate dimensions.

- Erecting wall studs: Attach wall studs to the base frame, maintaining consistent spacing and plumbness.

- Constructing the roof frame: Build the roof frame, ensuring the correct slope for efficient drainage. Attach this frame to the top of the wall studs.

- Attaching to the existing structure: Securely fasten the lean-to frame to the existing building using appropriate fasteners and ensuring proper structural support.

Sheathing and Roofing

Sheathing provides a solid surface for the exterior finish, while the roofing protects the shed's contents from the elements:

- Attaching sheathing: Install plywood or OSB sheathing to the walls and roof frame, ensuring proper overlap and secure fastening.

- Installing roofing: Install your chosen roofing material according to the manufacturer's instructions. Ensure proper overlapping and sealing to prevent leaks.

- Installing siding (optional): Apply your chosen siding material to the exterior walls, following the manufacturer's instructions.

Phase 3: Finishing Touches

The final phase involves adding finishing touches to enhance the functionality and aesthetics of your lean-to shed.

Door Installation

Install the door, ensuring proper alignment and secure fastening. Consider adding weatherstripping for improved insulation and weather protection.

Window Installation (optional)

If incorporating windows, install them carefully, ensuring proper sealing and weatherproofing.

Interior Finishing

Consider adding interior shelving or other organizational features to maximize storage space. You might also consider painting the interior walls for a more finished look.

Exterior Finishing

Apply a final coat of paint or sealant to protect the exterior of the shed from the elements. This will also enhance its aesthetic appeal.

Building your own lean-to shed is a rewarding project that enhances your property and provides valuable storage space. By carefully following these plans and taking your time, you can create a durable and functional addition to your backyard, transforming your outdoor space from cluttered to organized and efficient.

DIY Pallet Shed: Free Plans for Budget-Friendly Construction

DIY Pallet Shed: Free Plans for Budget-Friendly Construction

Tired of overflowing garages and cluttered yards? Yearning for extra storage space without breaking the bank? Then building your own pallet shed is the perfect solution! This comprehensive guide provides free plans and detailed instructions, empowering you to construct a functional and attractive storage shed using readily available and inexpensive reclaimed pallets. Prepare to transform scrap materials into a valuable addition to your property, all while enjoying a rewarding DIY project.

Gathering Your Materials: The Foundation of Your Pallet Shed

Before you even think about hammering a nail, you need to gather your materials. The beauty of this project lies in its resourcefulness. Reclaimed pallets form the heart of the shed, offering a surprisingly robust building material. Source your pallets responsibly; ensure they are free from chemicals and pests. Inspect each pallet carefully and discard any showing significant damage. Beyond pallets, you'll need essential tools and supplies. This includes: screws (exterior-grade are crucial!), a drill with various drill bits, a level, measuring tape, a saw (circular saw recommended), safety glasses, work gloves, and a sturdy hammer. Consider adding extra support with treated lumber for the base frame. Don't underestimate the importance of quality tools; they'll significantly impact the efficiency and outcome of your project.

Step-by-Step Construction: Building Your Pallet Haven

Creating a Solid Foundation:

Begin by constructing a level base for your shed. This is paramount for structural integrity. Use pressure-treated lumber to build a sturdy rectangular frame on a prepared level surface. Secure the frame using galvanized screws. Consider anchoring the frame to the ground using ground anchors for added stability, particularly in areas prone to strong winds. This foundational step will prevent your shed from sinking or shifting over time.

Assembling the Pallet Walls:

Now comes the rewarding part: assembling the pallet walls. Carefully inspect each pallet for loose boards and secure any wobbly components. You'll likely need to dismantle some pallets and re-arrange boards to create even wall sections. Attach the pallets to the base frame using long screws, ensuring each pallet is level and firmly attached. For increased stability, consider adding vertical supports within the pallet walls, particularly for taller structures.

Constructing the Roof:

With the walls securely in place, it's time to build the roof. For a simple design, opt for a gable roof. You'll need additional lumber to create the roof framing. Ensure the roof rafters are properly angled and securely fastened to the top of the walls. Cover the roof with plywood sheets and waterproof roofing material. Remember to leave adequate overhang to protect the walls from rain. This is your final line of defense against the elements, so take your time and ensure a secure and watertight seal.

Adding the Finishing Touches:

Once the structure is complete, you can add personal touches. Consider adding a door using reclaimed wood or purchasing a pre-made door. A simple latch mechanism will keep your belongings safe. You may want to paint or stain your pallet shed for added protection and aesthetic appeal. This is a great opportunity to personalize your shed and integrate it with the existing landscape. A little creativity can transform a simple structure into a charming addition to your backyard.

Tips for Success and Safety

Remember safety first! Always wear safety glasses and work gloves when using power tools. Take your time and double-check your measurements before making any cuts. Ensure all screws are fully tightened. Prioritize proper ventilation while working with paints or stains, and always follow the manufacturer's instructions. If you're unsure about any step, consult a more experienced DIYer or construction professional for guidance. This project is achievable for most DIY enthusiasts, but proper planning and caution will guarantee a safe and successful outcome.

Free Plans and Further Resources

While this article provides a comprehensive overview, access to detailed free plans is essential for a successful build. Many websites and online communities dedicated to DIY projects offer free downloadable plans for pallet sheds of varying sizes and designs. These plans often include detailed diagrams, material lists, and step-by-step instructions. Searching online for "free pallet shed plans" will provide numerous resources to get you started. Consider joining online forums and communities where you can connect with other DIY enthusiasts, share your progress, and seek advice when needed. Happy building!

How to Build a Small Pallet Shed: A Beginner's Guide to Outdoor Projects

How to Build a Small Pallet Shed: A Beginner's Guide to Outdoor Projects

Constructing a small shed from reclaimed pallets offers a cost-effective and environmentally conscious approach to expanding outdoor storage space. This guide provides a comprehensive overview of the process, from initial planning and material sourcing to final construction and finishing. While prior construction experience is beneficial, this project is achievable for dedicated beginners with careful planning and attention to detail.

Phase 1: Planning and Preparation

Before commencing construction, meticulous planning is paramount to ensure a successful outcome. This involves several key steps:

1.1 Defining Project Scope and Shed Specifications

Begin by clearly defining the purpose of your shed. Will it store gardening tools, bicycles, or other equipment? This determines the required size and internal layout. Consider the dimensions carefully; a smaller shed is easier to build but might limit storage capacity. Sketch a simple design, noting the desired length, width, and height. Factor in door placement and any internal shelving or partitions.

1.2 Sourcing and Assessing Pallets

Reclaimed pallets are the foundation of this project. Source them from local businesses, construction sites, or online marketplaces. Inspect each pallet thoroughly for signs of rot, pest infestation, or significant damage. Prioritize pallets constructed from pressure-treated lumber, which offers greater durability and resistance to decay. However, always ascertain the type of treatment used, as some chemicals may pose health risks. Ideally, aim for pallets of consistent size and quality to simplify construction.

1.3 Gathering Tools and Materials

Assemble the necessary tools and materials before beginning construction. This will streamline the process and prevent interruptions. The following list is a comprehensive starting point:

- Safety Gear: Safety glasses, work gloves, dust mask, hearing protection.

- Measuring and Marking Tools: Measuring tape, level, speed square, pencil.

- Cutting and Joining Tools: Circular saw or hand saw (for cutting pallets), hammer, pry bar, nails or screws, drill with appropriate drill bits, possibly a nail gun (for faster construction).

- Fasteners: Galvanized nails or screws (exterior-grade), appropriate-sized screws for joining pallet wood (consider using longer screws to increase sturdiness).

- Other Materials: Plywood or OSB for flooring and roofing, roofing felt or tar paper, exterior-grade paint or sealant (optional), hinges, door handle, possibly concrete blocks for the base (optional).

Phase 2: Shed Construction

With planning complete and materials gathered, the construction phase begins. This involves careful assembly and attention to detail.

2.1 Foundation Preparation

While a concrete slab is ideal for a permanent shed, a simpler approach for a small pallet shed is to use a gravel base or even a leveled ground area. This minimizes complexity and cost. Clear the chosen location of debris and level the ground. For a more robust base, consider laying down a layer of gravel and compacting it. This helps with drainage and provides a more stable foundation.

2.2 Pallet Wall Assembly

Assemble the pallet walls. Start by inspecting and cleaning the selected pallets. Remove any loose nails, splinters, or protruding elements. If necessary, disassemble parts of pallets to create more manageable pieces for building the walls. Ensure the walls are square and plumb using a level and speed square. Consider reinforcing the corners with additional bracing or longer screws to increase structural integrity. The height of your walls will determine the overall height of the shed. It's recommended to use at least two pallets per section of wall for stability. If your walls are longer than a single pallet, you will need to join them by securing them together.

2.3 Floor Construction

Construct the floor using plywood or OSB sheets. Cut the sheets to fit the interior dimensions of the pallet walls. Ensure the floor is level and securely fastened to the bottom of the pallet walls. This will provide a solid base for the shed and prevent the floor from sagging under weight.

2.4 Roof Construction

The roof is crucial for protecting the shed's contents. A simple gable roof is straightforward for beginners. Cut and assemble the roof supports using more pallets or additional lumber. Cover the supports with plywood or OSB and then apply roofing felt or tar paper for weatherproofing. Finally, consider adding shingles or other roofing material for a more durable finish.

2.5 Door Installation

Construct a door using pallets or additional lumber. This can be a simple single-pallet door or a more complex design depending on your skills and resources. Hang the door using appropriate hinges, and install a latch or handle for security. Consider using weather stripping for a better seal.

Phase 3: Finishing Touches

Once the structure is complete, focus on finishing touches to enhance aesthetics and durability.

3.1 Sealing and Painting

Apply a coat of exterior-grade sealant or paint to protect the wood from moisture and the elements. This significantly extends the lifespan of the shed. Choose colors that complement your surroundings.

3.2 Internal Finishing

Add interior features such as shelves or partitions to maximize storage space. You can use additional pallets or other lumber to build these features.

3.3 Landscaping and Final Clean-Up

Once construction is complete, tidy the surrounding area. Consider adding landscaping elements to enhance the overall look of your new shed and blend it with the garden.

Conclusion

Building a small pallet shed is a rewarding project that combines practicality with environmental responsibility. By following these steps and prioritizing safety and attention to detail, even novice builders can create a durable and functional outdoor storage solution. Remember to adapt the design and materials to your specific needs and skill level. Enjoy the process and the satisfaction of creating something lasting with your own hands.

Affordable Basic Shed Plans for Practical Storage Solutions

Affordable Basic Shed Plans for Practical Storage Solutions

Hey there! So, you're looking for a shed, huh? Something to tame that overflowing garage, finally get a handle on garden tools, or just create a little extra space. I get it! Storage solutions can feel overwhelming, and the cost of pre-built sheds can be, well, shed-loads of money! But don't worry, building your own basic shed doesn't have to break the bank. This guide is all about finding affordable, practical plans to get you started.

Choosing the Right Shed Size and Style

Before you even think about hammering a nail, you need a plan. And the first part of that plan? Figuring out what kind of shed you actually need. Too small, and you'll be frustrated. Too big, and you'll be spending more than you need to on materials.

Considering Your Needs:

What are you planning to store? Lawn mowers and gardening tools? Bikes and outdoor furniture? Sporting equipment? The contents will dictate the size and features you need. A small 4ft x 6ft shed might be perfect for basic tools, but you'll need something much larger for larger equipment or multiple items.

Basic Shed Styles:

You don't need anything fancy for a basic shed. Simple designs are often the most cost-effective. Consider these:

- Single-slope shed: This is the simplest design, with just one sloped roof. It's easy to build and requires less material.

- Gable shed: Features a triangular roof, offering more headroom inside. A bit more complex to build but still very manageable for a DIY project.

- Lean-to shed: This style is attached to an existing structure, like a house or garage, making it perfect for saving space.

Keep in mind that the more elaborate the design, the more expensive it will be to build. Simplicity is your friend when aiming for affordability.

Finding Affordable Shed Plans

Now for the fun (and budget-friendly!) part. There are tons of resources for finding affordable shed plans. You don't need to hire an architect!

Online Resources:

The internet is a treasure trove of free and low-cost shed plans. Websites like Pinterest, Instructables, and various home improvement blogs often have detailed plans with diagrams and material lists. Just remember to carefully check the reviews and comments before committing to a plan.

Books and Magazines:

Your local library might surprise you! Many libraries have books on shed construction with a range of plans. Home improvement magazines also frequently feature shed plans â€" sometimes even as part of larger DIY projects.

Customizing Your Plan:

Once you've found a basic plan, don't be afraid to tweak it to fit your needs and budget. For example, you could simplify the door design or use less expensive materials. Just ensure any modifications are structurally sound.

Choosing Materials and Keeping Costs Down

Material costs can significantly impact your overall budget. Smart material choices are key to keeping things affordable.

Prioritize Treated Lumber:

Pressure-treated lumber is crucial, especially for the foundation and base. It resists rot and insects, extending the life of your shed and saving you money on future repairs. However, don't overdo it; using treated lumber everywhere might not be necessary or cost effective.

Consider Recycled Materials:

Think creatively! Can you repurpose some materials you already have? Reclaimed wood, old pallets (carefully checked for safety!), or even repurposed windows can add character and save you money. Just ensure they're structurally sound enough for the project.

Shop Around for the Best Prices:

This is a no-brainer! Don't just buy materials from the first store you find. Check lumber yards, home improvement stores, and even online retailers to compare prices. You might be surprised at the difference.

Plan Your Cuts Carefully:

Minimize waste by planning your cuts meticulously. Use a good quality measuring tape and create accurate cutting diagrams. This will save you money on lumber and reduce time spent on re-cuts.

Building Your Shed: A Step-by-Step Guide (Simplified)

This is a very simplified overview, remember to consult your chosen plan for detailed instructions.

- Prepare the Ground: Level the ground and create a solid base. This could be concrete, a gravel base, or even pressure-treated lumber skids.

- Build the Floor: Construct the floor frame according to your plan, ensuring it's level and square. Install your floor boards.

- Erect the Walls: Assemble the wall frames and attach them to the floor. Use appropriate fasteners and bracing.

- Install the Roof: Build and attach the roof trusses or rafters. Add roofing material (consider affordable options like metal roofing).

- Add the Doors and Windows: Install your doors and windows, ensuring they fit properly and are securely fastened.

- Finishing Touches: Apply a weatherproof sealant or paint to protect the wood. Consider adding shelving or other interior features.

Remember, safety first! Wear appropriate safety gear like gloves, safety glasses, and hearing protection. If you're unsure about any step, consult a professional or a more experienced DIYer.

Commonly Asked Questions

Let's tackle some common questions people have about building their own sheds:

- Q: Do I need a building permit? A: This depends on your location and the size and complexity of your shed. Check with your local building department to avoid potential fines.

- Q: How long does it take to build a shed? A: The timeframe varies greatly depending on size, complexity, your experience level, and the time you can dedicate to the project. A simple shed can take a weekend for an experienced builder, while a more complex one could take several weeks.

- Q: Can I build a shed without any experience? A: While it's possible, it's definitely more challenging. Start with a simple plan, take your time, and don't hesitate to seek help from experienced DIYers or online forums if you get stuck.

- Q: How much will it cost to build a basic shed? A: The cost varies significantly based on size, materials, and location. But you can often build a basic shed for several hundred dollars less than a pre-built one.

- Q: What tools do I need? A: You'll need basic tools like a hammer, saw, measuring tape, drill, level, and screwdrivers. More specialized tools may be needed depending on your chosen plan.

Building your own shed can be a rewarding experience. It saves money, gives you a sense of accomplishment, and provides you with valuable storage space. So get planning, get building, and enjoy your new shed!

DIY Simple Pallet Shed: Easy Plans for a Quick Build

DIY Simple Pallet Shed: Easy Plans for a Quick Build

Constructing a simple shed from reclaimed pallets presents a cost-effective and environmentally conscious alternative to purchasing a pre-fabricated structure. This guide provides comprehensive instructions for building a basic pallet shed, emphasizing ease of construction and readily available materials. While requiring some basic carpentry skills, this project is achievable for a moderately skilled DIY enthusiast with appropriate tools. Careful planning and attention to detail will ensure a robust and weather-resistant outcome.

I. Planning and Material Acquisition

The initial phase involves meticulous planning to ensure the project's success. This encompasses determining the shed's dimensions, sourcing suitable pallets, and gathering the necessary tools and additional materials.

A. Determining Dimensions and Site Selection

The shed's dimensions are dictated by its intended purpose and available space. Consider the storage needs and the footprint of the proposed location. Smaller sheds (e.g., 6ft x 4ft) are simpler to construct, requiring fewer pallets. Larger structures demand more pallets and may necessitate more advanced techniques. Ensure the chosen site provides a level and stable foundation, free from obstructions such as underground utilities.

B. Sourcing Pallets

Reclaimed pallets form the primary structural element of the shed. Sourcing these requires careful consideration. Prioritize pallets in good condition, exhibiting minimal damage or rot. Inspect for loose nails or broken boards, which may compromise structural integrity. Pallets treated with chemical preservatives (e.g., methyl bromide) should be avoided due to potential health risks. Confirm the pallet's treatment status through markings before use. The quantity needed will depend on the shed's size and design.

C. Acquiring Additional Materials and Tools

Beyond pallets, several supplementary materials are crucial for a complete structure. This includes:

- Concrete blocks or a suitable foundation: To create a level base for the shed.

- Roofing material: Tarpaulin, corrugated metal sheeting, or other weather-resistant material.

- Plywood or OSB sheeting: To cover gaps between pallets and enhance weather resistance.

- Nails, screws, and screws (various sizes): For securing the pallets and other materials.

- Wood preservative and sealant: To protect the wood from moisture and insect damage.

- Hinges and a latch: For the shed door.

Essential tools include:

- Hammer

- Screwdriver (or drill/driver)

- Measuring tape and level

- Saw (hand saw or circular saw)

- Safety glasses and gloves

II. Construction Process

The construction is divided into several stages, ensuring a methodical and organized approach. Prioritize safety throughout the process, wearing appropriate protective gear.

A. Foundation Preparation

A stable base is paramount. Create a level foundation using concrete blocks laid on compacted ground. Adjust the height of the blocks to ensure a level surface. Alternatively, a simple gravel base may suffice for smaller, less weight-bearing sheds. Ensure the foundation extends beyond the shed's dimensions for stability.

B. Pallet Assembly for Walls

Begin assembling the walls. This involves carefully stacking pallets vertically, ensuring alignment and securing them with screws or nails. Inspect each pallet for structural integrity prior to use. Use longer screws to pass through multiple pallets, enhancing structural rigidity. For taller structures, consider using additional bracing or support beams between pallets to prevent racking.

C. Constructing the Roof

The roof design can vary depending on complexity. A simple gable roof is suitable for this project. This may involve cutting pallets to create angled roof supports, or using additional lumber to create a frame. Securely attach the roofing material to the frame, ensuring adequate overlap to prevent water ingress. Ensure the roof has sufficient overhang to protect the walls from rain.

D. Door Installation

Create the door by securing several pallets together. Install hinges on one side and a latch on the other. Ensure the door fits snugly within its frame. For improved weather resistance, consider sealing gaps around the door frame with sealant or weather stripping.

E. Finishing Touches

Once the structure is complete, apply a wood preservative and sealant to protect the wood from the elements. This will extend the shed's lifespan significantly. Fill any gaps or cracks with wood filler and sand smooth before applying sealant. Consider adding additional features such as shelves or a lock for enhanced functionality and security.

III. Considerations for Enhanced Durability

To maximize the shed's longevity, several measures can enhance its durability and weather resistance.

A. Pallet Selection and Preparation

Carefully select pallets with minimal signs of wear, rot, or pest damage. Clean the pallets thoroughly before assembly, removing any debris or loose nails. Consider reinforcing weak points with additional bracing or supports. Applying a wood preservative prior to assembly is also advisable.

B. Weatherproofing

Effective weatherproofing is crucial. Seal all gaps between pallets using appropriate sealant or caulk. Use weather-resistant roofing material with sufficient overlap to prevent leaks. Consider adding a layer of plywood or OSB sheeting to the exterior walls to further improve weather resistance.

C. Foundation Stability

A robust foundation is essential. Ensure the foundation is level and able to support the weight of the shed. Use concrete blocks or a suitable alternative that can withstand the elements. If using a gravel base, ensure it is well-compacted and adequately leveled. Consider using a concrete slab for a more permanent and stable base.

D. Regular Maintenance

Regular inspection and maintenance are vital. Check for any signs of damage, rot, or pest infestation. Re-apply sealant or wood preservative as needed. Clean debris and address any potential problems promptly to prevent further damage and maintain the structure's integrity.

By following these detailed plans and implementing the suggested enhancements, you can successfully construct a durable and functional pallet shed, providing valuable storage space while utilizing readily available and cost-effective materials. Remember to prioritize safety throughout the construction process.

How to Make a Pallet Shed DIY: A Simple Project for Your Yard

How to Make a Pallet Shed DIY: A Simple Project for Your Yard

Constructing a pallet shed offers a cost-effective and environmentally friendly solution for additional storage in your yard. This project, while seemingly straightforward, requires meticulous planning and execution to ensure structural integrity and longevity. This comprehensive guide details the process, from initial design considerations to final finishing touches, enabling even novice DIY enthusiasts to successfully complete this rewarding endeavor.

Phase 1: Planning and Preparation

The foundation of any successful construction project lies in thorough planning. Before acquiring any materials, a detailed plan must be formulated, encompassing design specifications, material acquisition, and a realistic timeline.

A. Design Considerations

The dimensions of your pallet shed should align with your storage needs and the available space in your yard. Consider the following factors:

- Size and Dimensions: Determine the required internal space based on the items you intend to store. Standard pallet dimensions (typically 48 inches x 40 inches) should inform your overall design.

- Location: Select a level, stable location that is readily accessible yet unobtrusive. Ensure compliance with any local building regulations regarding setbacks and permits.

- Door Placement and Size: Strategically plan the location and size of the door to optimize accessibility and minimize obstruction. Consider the size of items you will be moving in and out of the shed.

- Roof Style: A simple gable roof is generally the easiest to construct for a pallet shed. Other styles, while aesthetically pleasing, may increase complexity.

- Foundation: Decide on a suitable foundation. Options include a concrete slab, compacted gravel base, or even raised wooden platform.

B. Material Acquisition and Preparation

Sourcing materials is crucial. While reclaimed pallets are cost-effective, careful inspection is vital. Select pallets that are structurally sound, free from rot, significant pest infestation, and any hazardous materials.

- Pallet Selection: Inspect each pallet for structural integrity. Look for cracks, broken boards, or signs of insect damage. Prioritize pallets made from pressure-treated lumber if you anticipate exposure to moisture.

- Additional Lumber: You will likely require additional lumber for structural support, including framing, roofing, and door construction. Purchase high-quality, appropriately treated lumber.

- Fasteners: Choose appropriate fasteners, such as galvanized nails, screws, or bolts, to ensure robust connections. Consider using exterior-grade screws for added durability.

- Roofing Material: Select a suitable roofing material such as corrugated metal sheeting, asphalt shingles, or tar paper. Consider the local climate and aesthetics when making your choice.

- Other Materials: Acquire any necessary additional materials, including hinges, a door handle, paint or sealant, and safety equipment (gloves, safety glasses).

C. Tool Acquisition

Ensure you have all the necessary tools before commencing construction. This will prevent delays and ensure smooth workflow. Essential tools include:

- Measuring Tape and Level: Accurate measurements are paramount for structural integrity.

- Hammer or Nail Gun: For efficient fastening of materials.

- Saw (Circular or Hand): To cut lumber to the required dimensions.

- Drill and Drill Bits: For pre-drilling holes to prevent wood splitting and for using screws.

- Screwdriver (Electric or Manual): To drive screws securely.

- Safety Glasses and Gloves: To protect against injury.

Phase 2: Construction

With planning complete and materials gathered, the construction phase can begin. This involves building the shed's frame, walls, roof, and door.

A. Foundation Construction

Begin by preparing the foundation. For a simple approach, a compacted gravel base provides adequate drainage. For a more permanent solution, consider a concrete slab. Ensure the foundation is level and stable to prevent future settling.

B. Frame Assembly

Construct the frame using additional lumber. The frame provides structural support for the entire shed. Ensure all corners are square and securely fastened. The dimensions of the frame should align with your design specifications.

C. Wall Construction

Attach the pallets to the frame, ensuring proper alignment and spacing. Use appropriate fasteners to secure the pallets to the frame. If necessary, cut and adjust pallets to fit the frame precisely. Consider bracing the walls for added stability.

D. Roof Construction

Construct the roof frame based on your chosen roof style (e.g., gable). Securely attach the roof frame to the top of the walls. Then, install the chosen roofing material, ensuring proper overlap and weather-tight sealing. Consider adding additional support beams or rafters for larger structures.

E. Door Installation

Construct the door frame using additional lumber. Attach the frame to the opening in the wall. Install the door, hinges, and handle. Ensure the door operates smoothly and securely.

Phase 3: Finishing Touches

Once the structure is complete, apply finishing touches to enhance aesthetics and longevity.

A. Sealing and Painting

Apply a weather-resistant sealant to all exposed wood surfaces to protect against moisture damage. Painting can improve the aesthetics and add further protection from the elements. Choose exterior-grade paints suitable for wood.

B. Final Inspections and Adjustments

Conduct a final inspection to ensure all connections are secure, the roof is watertight, and the door operates correctly. Make any necessary adjustments or repairs before considering the project complete.

Conclusion

Building a pallet shed is a rewarding DIY project that combines functionality with environmental responsibility. By following these detailed steps, meticulously planning, and carefully executing each phase, you can create a durable and aesthetically pleasing addition to your yard. Remember to prioritize safety throughout the construction process and enjoy the satisfaction of creating something lasting with your own hands.

DIY Lean-To Shed Build: Turning Your Backyard into a Storage Haven

DIY Lean-To Shed Build: Turning Your Backyard into a Storage Haven

So, you're staring at that overflowing garage, that cluttered patio, and that nagging feeling that you *really* need more storage space. Sound familiar? Well, grab your tool belt (or borrow your neighbor's!), because we're about to embark on a rewarding journey: building your very own lean-to shed! No, you don't need to be a seasoned carpenter. With a bit of planning, some elbow grease, and a healthy dose of patience, you can transform a corner of your backyard into a tidy, functional storage solution.

Planning Your Lean-To Shed Paradise

Before you even think about touching a saw, let's get organized. This isn't rocket science, but a little planning goes a long way in avoiding headaches (and potential redos!).

Choosing the Perfect Spot

Where will your new storage haven reside? Consider these factors:

- Proximity to the house: A lean-to shed usually attaches to an existing structure (like a house or garage), making it easier to run electricity or plumbing (if needed). But make sure you have enough space for the door to open easily!

- Ground conditions: Is the ground level and stable? You'll need a solid foundation. Uneven ground will lead to a wonky shed, and nobody wants that.

- Sun exposure: Do you need a sunny spot or a shaded one? Think about what you'll be storing. Some items are sensitive to moisture and sunlight.

- Local regulations: Check your local building codes and HOA rules. There might be restrictions on shed size, materials, or placement.

Designing Your Dream Shed

Now for the fun part: designing your shed! Consider the following:

- Size: How much storage space do you actually need? Be realistic â€" it's easy to overestimate.

- Materials: Pressure-treated lumber is a popular and affordable choice for the frame, offering good durability. For the siding, you've got tons of options: wood, vinyl, metal... the choice is yours!

- Roofing: Asphalt shingles are a classic, budget-friendly option. Metal roofing is durable and long-lasting, but a bit more expensive.

- Door: A standard single door is often sufficient for a lean-to, but a double door might be necessary for larger items.

Gathering Your Supplies and Tools

Once you have your design finalized, create a detailed list of all the materials and tools you'll need. Trust me, this will save you countless trips to the hardware store. A well-stocked toolbox is your best friend on this project!

Essential Tools (just a starting point, you might need more!):

- Measuring tape

- Level

- Shovel

- Post hole digger (or a strong back!)

- Circular saw or hand saw

- Drill

- Screwdriver bits

- Hammer

- Safety glasses

- Work gloves

Building Your Lean-To Shed: A Step-by-Step Guide

Okay, let's get our hands dirty! This is a simplified overview. For detailed instructions, refer to online tutorials and building plans specific to your chosen design. Remember, safety first!

Foundation

A solid foundation is crucial. Depending on your ground conditions and shed size, you might opt for concrete piers, a gravel base, or even a simple wooden frame resting on concrete blocks. Make sure it's level!

Framing

Build the frame of your shed using pressure-treated lumber. This involves constructing the floor frame (if not using a concrete slab), walls, and roof rafters. Use a level constantly to ensure everything is square and plumb. Pre-drilling holes before screwing will prevent the wood from splitting.

Siding and Roofing

Once the frame is complete, you can add your chosen siding material. This is where you'll see your shed start to take shape! Follow the manufacturer's instructions for installation. After the siding, install your roofing material, ensuring proper overhang for protection.

Finishing Touches

Finally, add the door, windows (if you've included them in your design), and any other finishing details. You might want to paint or stain your shed to protect it from the elements and give it a personal touch.

Tips for Success

Building a shed is a rewarding experience, but here are a few tips to make the process smoother:

- Take your time: Don't rush the process. Accuracy is key, especially when it comes to framing.

- Work with a buddy: Having an extra pair of hands can be incredibly helpful, especially for lifting and maneuvering larger pieces of lumber.

- Check your measurements repeatedly: Double-checking your measurements throughout the process can prevent costly mistakes.

- Clean up as you go: Keeping your work area organized will make the entire project less stressful.

- Celebrate your accomplishment! Once your shed is complete, take a moment to admire your hard work. You deserve it!

Commonly Asked Questions

Q: Do I need a building permit?

A: It depends on your local regulations. Many municipalities require permits for sheds exceeding a certain size or that include electrical or plumbing. Check with your local building department.

Q: How long does it take to build a lean-to shed?

A: The timeframe varies depending on the size and complexity of your design, as well as your experience level. A small lean-to could take a weekend, while a larger one might take several.

Q: How much does it cost to build a lean-to shed?

A: The cost depends heavily on the materials you choose and the size of your shed. You can build a basic lean-to for a few hundred dollars, while more elaborate designs can cost significantly more.

Q: Can I build a lean-to shed without any prior experience?

A: Yes, but it's crucial to follow detailed instructions, take your time, and possibly enlist the help of a more experienced builder for guidance. There are many excellent online resources and tutorials available.

Q: What if I run into problems?

A: Don't panic! There are tons of online resources, forums, and YouTube channels dedicated to DIY projects. Search for your specific problem, and you'll likely find a solution. Don't hesitate to ask for help from experienced friends or family members.

Happy building!

Download Pallet Shed Plans PDF for Easy and Affordable DIY Storage

Download Pallet Shed Plans PDF for Easy and Affordable DIY Storage

Hey there, fellow DIY enthusiasts! Are you tired of tripping over garden tools, staring at overflowing storage bins, or just generally feeling overwhelmed by clutter? Then let's talk about building your own pallet shed! It's cheaper than buying a pre-made shed, a surprisingly rewarding project, and a fantastic way to get organized. I'm going to walk you through everything you need to know to build your very own, awesome pallet shed, including where to find those awesome free pallet plans!Why Build a Pallet Shed?

Before we dive into the nitty-gritty, let's talk about why building a pallet shed is such a great idea. First off, the cost savings are significant. Reclaimed pallets are often free (or very cheap) if you know where to look â€" more on that later! You're basically repurposing materials, which is super eco-friendly. Plus, the design possibilities are endless. You can tailor your shed to fit your specific needs and style, making it a truly unique addition to your property. And finally, building something with your own two hands is immensely satisfying!

Finding Your Free Pallet Shed Plans PDF

Now, let's get to the good stuff: those free pallet shed plans. You won't find a single, universally perfect plan because every shed is unique. But there are tons of great resources online where you can find detailed blueprints and guides. I recommend searching for terms like "free pallet shed plans PDF," "DIY pallet shed blueprints," or "reclaimed pallet storage building plans." Here are a few places to start your search:

- DIY and home improvement websites: Many websites dedicated to DIY projects offer free plans, often with photos and step-by-step instructions. Think sites like Pinterest, Instructables, and others. Just be sure to check the reviews before committing to a plan!

- YouTube: YouTube is a goldmine of DIY videos. Search for "pallet shed build" and you'll find tons of videos showing the entire construction process, from start to finish. Pay attention to the comments section - often, people will point out potential issues or improvements to the plans shown.

- Online forums: Join online forums or communities dedicated to DIY and woodworking. You can ask questions, share your progress, and possibly even find someone willing to share their own plans.

When choosing your plans, consider factors like:

- Size: How much storage space do you actually need?

- Complexity: Are you a beginner or an experienced DIYer? Choose plans that match your skill level.

- Materials: Do the plans clearly specify the materials you'll need, and are those materials readily available in your area?

- Clarity: Are the instructions clear, concise, and easy to understand? Good diagrams are essential!

Sourcing Your Pallets

Now that you've got your plans, let's talk about the star of the show: the pallets! Finding free or inexpensive pallets is key to keeping this project budget-friendly. Here are some places to look:

- Local businesses: Contact supermarkets, construction sites, and shipping companies. Many businesses are happy to get rid of their used pallets.

- Craigslist and Facebook Marketplace: You can often find pallets for sale or even free for pickup on these online classifieds.

- Pallet suppliers: While not always free, pallet suppliers sometimes sell used pallets at a very low price.

Important note: Before using any pallet, make sure it's been properly treated and is free from harmful chemicals or pests. Check for any stamps or markings indicating treatment. HT (heat treated) is generally safe. MB (methyl bromide) is not! Avoid using pallets marked MB.

Tools and Materials You'll Need

Beyond the pallets themselves, you'll need a few essential tools and materials. The exact list will depend on your chosen plans, but here's a general overview:

- Measuring tape and level: Crucial for accurate measurements and ensuring your shed is square.

- Saw (circular saw or hand saw): For cutting pallets to size.

- Hammer and nails (or screws and screwdriver): For assembling the pallet structure.

- Drill (optional but highly recommended): Makes the job much faster and easier.

- Safety glasses and gloves: Always prioritize your safety!

- Wood glue (optional): Adds extra strength to the joints.

- Other materials: Depending on the plan, you may need roofing materials, screws, brackets, etc.

Building Your Pallet Shed: A Step-by-Step Guide (General Overview)

This is where things get really project-specific, based on your downloaded plans. A generic step-by-step guide is impossible, but here’s a generalized outline:

- Prepare the pallets: Clean, inspect, and cut the pallets as needed according to your plans.

- Build the foundation: This might involve creating a simple base using more pallets, concrete blocks, or a wooden frame.

- Assemble the walls: Connect the pallets to form the walls of your shed. Use nails, screws, and possibly wood glue for extra strength.

- Build the roof: Construct the roof frame using more pallets or other lumber. Add roofing material for protection from the elements.

- Add doors and windows (optional): If your plans include doors and windows, install them now.

- Finishing touches: Sand down any rough edges, paint or stain your shed (optional), and add any other desired features.

Tips for Success

- Start small: Your first pallet project doesn't need to be a massive undertaking. A small shed is a great way to gain experience.

- Take your time: Rushing can lead to mistakes. Work at a comfortable pace and don't be afraid to ask for help.

- Check measurements repeatedly: Accuracy is key to a structurally sound shed.

- Use appropriate safety gear: This is not a game â€" protect your eyes and hands!

- Have fun!: Building something yourself is incredibly rewarding. Enjoy the process!

Frequently Asked Questions

Q: How long does it take to build a pallet shed?

A: This depends heavily on the size and complexity of the shed, as well as your experience. A small, simple shed could take a weekend, while a larger, more complex one might take several weeks.

Q: How much does it cost to build a pallet shed?

A: The cost will largely depend on whether you find free pallets. If you source free pallets, your costs will mostly be for tools (if you don't already own them), screws/nails, and roofing material. You could build a basic shed for under $100.

Q: Do I need any special permits to build a pallet shed?

A: Check with your local government's building codes department. Depending on your location and the size of your shed, you may or may not need a permit.

Q: What kind of roofing material should I use?

A: Many options exist, including corrugated metal roofing, tarps, or even recycled materials like plastic sheeting. Choose something that fits your budget and the climate in your area.

Q: Can I use pressure-treated pallets?

A: While possible, it's generally recommended to avoid using pressure-treated pallets unless you know the specific chemicals used and their safety. Untreated or HT-treated pallets are preferable for safety reasons.

Happy building!

Wednesday, 20 November 2024

Create a Low-Cost Pallet Shed with These Detailed PDF Plans

Build Your Dream Pallet Shed: Low-Cost, Detailed PDF Plans Included

Tired of overflowing garages and cluttered yards? Dreaming of a practical storage solution without breaking the bank? Then look no further! This article provides you with a comprehensive guide to building your very own low-cost pallet shed, complete with detailed PDF plans you can download and start using immediately. We'll walk you through each step of the process, from sourcing materials to the final touches, ensuring you create a sturdy and functional storage space that enhances your property.

Why Choose a Pallet Shed?

Pallet sheds offer a fantastic blend of affordability and practicality. Reclaimed pallets, often readily available for free or at minimal cost from businesses, serve as the primary building material. This dramatically reduces the upfront investment compared to traditional shed construction. Beyond the cost savings, building a pallet shed presents a rewarding DIY project, allowing you to customize the size and features to perfectly fit your needs and aesthetic preferences. You'll gain a sense of accomplishment knowing you built it yourself, while also contributing to a more sustainable approach to construction by repurposing materials.

Gathering Your Materials and Tools

Before you dive into construction, gather your materials. This involves more than just pallets; you'll need additional components to ensure strength and weather resistance. The exact quantities will depend on your chosen shed dimensions (detailed in the downloadable PDF plans). However, you can expect to need:

- Reclaimed pallets (inspect carefully for damage and pests)

- Strong screws and nails (galvanized for weather resistance)

- Wood treatment (to protect against rot and pests)

- Roofing material (tar paper, corrugated metal, or shingles)

- Optional: Plywood or sheet metal for siding (for a more finished look)

- Optional: Hardware for a door and/or window

As for tools, you’ll need the basics: a hammer, screwdriver (or drill with various bits), saw (circular saw recommended for efficient cutting), measuring tape, level, and safety glasses.

Step-by-Step Construction Guide (Refer to PDF Plans)

The detailed PDF plans (available for download â€" link to be inserted here) provide comprehensive, step-by-step instructions with diagrams. These plans will guide you through the crucial stages, including:

Foundation Preparation:

Begin by preparing a level foundation. This could involve a simple gravel base or a more substantial concrete slab, depending on your soil conditions and desired shed stability. The PDF plans detail the foundation requirements based on the shed's size and design.

Pallet Assembly and Framing:

The plans illustrate how to assemble the pallet walls, ensuring they are sturdy and properly aligned. This involves connecting pallets securely using screws and bracing as needed. The framing will provide the structural integrity of your shed.

Roof Construction:

Construct the roof using the detailed diagrams in the PDF plans. This may involve creating roof trusses or a simpler gable roof design. Ensure proper overlap of roofing materials for weather protection.

Finishing Touches:

Once the structure is complete, add finishing touches. This might include adding a door, window, and applying wood treatment to improve durability and weather resistance. Consider painting or staining the pallets for a more aesthetically pleasing result.

Download Your Free PDF Plans Now!

Ready to start your pallet shed project? Download your comprehensive PDF plans (link to be inserted here) and begin transforming your outdoor space today! Remember to always prioritize safety when working with tools and materials. With careful planning and these detailed instructions, you'll soon enjoy your own custom-built pallet shed â€" a testament to your DIY skills and resourcefulness.

Tuesday, 19 November 2024

How to Build a Reliable 8x12 Lean-To Shed for Your Garden Tools

Building Your Dream 8x12 Lean-To Shed: A Gardener's Guide

So, you're ready to ditch the overflowing tool chest and give your garden tools the five-star treatment they deserve? Building an 8x12 lean-to shed is a fantastic way to do just that! It’s a manageable project, even for a DIY beginner, and the sense of accomplishment? Priceless. Let's dive into how to build this super useful garden haven.

Planning and Preparation: Laying the Foundation for Success

Before you even think about hammering a nail, careful planning is key. This isn't about rushing; it's about getting it right the first time. Think of it as planting the seeds for a successful build!

1. Location, Location, Location!

Where will your magnificent shed reside? Consider proximity to your garden (less hauling!), access to electricity (if you want lighting or power tools), and sunlight exposure (for drying tools). Ensure it's on level ground to avoid future headaches.

2. Permits and Regulations

Check with your local council or homeowner's association. You might need a permit depending on the size and location of the shed. It's better to be safe than sorry and avoid potential fines down the line. This usually includes checking for any setback requirements from your property line.

3. Choosing Your Materials

This is where the fun begins! But remember, quality materials make a huge difference in the longevity of your shed. Consider:

- Pressure-treated lumber: Essential for the base and framing to resist rot and insects.

- Plywood or OSB sheathing: For the walls and roof, offering a solid and weather-resistant surface.

- Roofing material: Asphalt shingles are a common and affordable choice, but metal roofing offers superior durability.

- Fasteners: Use galvanized nails and screws to prevent rust.

- Concrete blocks or a gravel base: For a solid foundation.

4. Tools of the Trade

Gather your tools before you start! You’ll need a measuring tape, level, saw (circular saw or hand saw), drill, hammer, shovel, post hole digger (if using posts), and safety gear (safety glasses, gloves). A post-hole digger can really make foundation prep faster and easier. Trust me on this one!

Building the Foundation: A Solid Start

A sturdy foundation is the cornerstone of a reliable shed. There are a couple of popular options:

1. Concrete Block Foundation

This is a more permanent and robust option. Level the ground, then lay down a layer of gravel for drainage. Place your concrete blocks, ensuring they’re level and plumb. You can even use a spirit level for this for extra accuracy.

2. Gravel Base

A simpler, quicker option, ideal for temporary or lighter sheds. Level the ground, then lay down a thick layer of compacted gravel. This will provide a stable base, but won't be as robust as concrete blocks.

Framing and Walls: Constructing the Skeleton

Now for the exciting part â€" building the structure! This involves creating the framework for your walls and roof.

1. Building the Frame

Construct the frame using pressure-treated lumber. Cut the lumber to the correct size and securely fasten the pieces together using screws and appropriate joinery. Remember to use a level constantly to ensure everything is square and plumb. This is crucial for a stable and attractive shed.

2. Attaching the Sheathing

Once the frame is complete, attach the plywood or OSB sheathing to the exterior. This will provide a solid surface for your siding and will help to keep the elements out. Make sure the sheathing overlaps appropriately to prevent water from getting in.

Roofing: Protecting Your Investment

The roof is the final shield against the elements. Get this right, and your tools will stay dry and happy for years to come.

1. Building the Roof Frame

Construct the roof frame using pressure-treated lumber. The design depends on the type of roof you choose (e.g., a simple gable roof is relatively straightforward). Ensure the rafters are evenly spaced and securely attached to the wall frame.

2. Installing the Roofing Material

Lay down your chosen roofing material (asphalt shingles, metal sheets, etc.) according to the manufacturer's instructions. This usually involves nailing or screwing the material to the rafters. Take your time and ensure proper overlap for waterproofing.

Finishing Touches: Adding the Final Details

You're nearly there! Now it's time to add those finishing touches that will transform your shed from a basic structure into a functional and attractive space.

1. Doors and Windows

Install a sturdy door to keep your tools secure. You might also want to add windows for ventilation and natural light. This will make the shed more pleasant to work in and will help to keep it dry.

2. Shelves and Organization

Once the shed is complete, install shelves and other organizational features to maximize storage space and keep your tools neatly arranged. This will make it much easier to find the tools you need when you need them.

3. Painting or Staining

Consider painting or staining the exterior to protect the wood from the elements and add a personal touch. Choose a weather-resistant paint or stain that's suitable for exterior use.

Commonly Asked Questions

Q: How long does it take to build an 8x12 lean-to shed?

A: This depends on your experience level and how much time you can dedicate to the project. A skilled builder might complete it in a weekend, while a beginner might take a few weeks, working in stages.

Q: How much does it cost to build an 8x12 lean-to shed?

A: The cost varies significantly based on the materials you choose. Expect to spend anywhere from a few hundred to a few thousand dollars.

Q: Do I need any special skills to build a shed?

A: Basic carpentry skills are helpful, but many online resources and tutorials can guide you through the process. Don’t be afraid to ask for help from more experienced friends or family members!

Q: Can I build this shed myself, or should I hire a contractor?

A: Whether you DIY or hire a contractor depends on your comfort level with carpentry and your available time. If you're comfortable with the project, DIY can be a rewarding experience. If you're not confident, hiring a contractor will save you time and stress. It’s completely your call!

Building your own 8x12 lean-to shed is a rewarding project that will give you a fantastic space for your gardening tools. Remember to take your time, plan carefully, and enjoy the process. Happy building!

Step-by-Step 8x12 Shed Plans with Porch: Build Your Dream Outdoor Shed

Step-by-Step 8x12 Shed Plans with Porch: Build Your Dream Outdoor Shed

This comprehensive guide provides detailed instructions for constructing an 8x12 shed with an attached porch. The project, while ambitious, is achievable for competent DIY enthusiasts with basic carpentry skills. Careful planning and meticulous execution are paramount to ensuring a structurally sound and aesthetically pleasing finished product. This guide assumes a familiarity with common woodworking tools and techniques. Always prioritize safety and consult relevant building codes in your area before commencing construction.

I. Planning and Preparation

A. Site Selection and Preparation

Choosing the right location is crucial. Consider factors such as sunlight exposure, proximity to utilities, drainage, and access for construction and future use. The ground must be level; significant leveling may necessitate excavation and the installation of a compacted gravel base. Ensure adequate clearance around the shed for ventilation and ease of access.

B. Material Selection and Acquisition

The materials list will vary based on personal preferences and local availability. However, a typical list includes:

- Pressure-treated lumber for the foundation, framing, and porch supports (4x4s, 2x4s, 2x6s)

- Exterior-grade plywood or OSB for sheathing

- Roofing material (shingles, metal, etc.)

- Siding (vinyl, wood, metal, etc.)

- Doors and windows

- Hardware (nails, screws, hinges, handles, etc.)

- Concrete (for a concrete foundation, optional)

- Gravel (for a gravel base, optional)

- Building wrap (optional, but recommended for weather protection)

Obtain accurate measurements and purchase materials with a small buffer to account for potential errors or unforeseen needs. Consider purchasing all lumber from the same batch to ensure consistent color and grain.

C. Permitting and Inspections

Check with your local building department to determine if permits are required for the construction of your shed. Familiarize yourself with any relevant building codes and regulations. Inspections may be required at various stages of construction. Failure to obtain necessary permits or comply with building codes could result in fines or legal action.

II. Foundation Construction

A. Concrete Slab Foundation (Recommended)

Excavate the area to a depth suitable for your local frost line and add a compacted gravel base for drainage. Construct a formwork and pour a reinforced concrete slab. Allow sufficient time for the concrete to cure completely before proceeding with framing.

B. Gravel Base Foundation

An alternative to a concrete slab, a compacted gravel base provides a stable foundation, but may not be suitable for all soil types or climates. Level the ground thoroughly and compact a layer of gravel, ensuring proper drainage. Construct a pressure-treated lumber sill plate on top of the gravel base.

III. Framing the Shed and Porch

A. Floor Framing

Construct the floor joists using pressure-treated lumber, ensuring proper spacing and support. Install the subflooring (plywood or OSB) securely.

B. Wall Framing

Build the wall frames using 2x4s or 2x6s, ensuring proper bracing and alignment. Install window and door openings as per your design. Use appropriate fasteners to ensure structural integrity.